Blog

What Is Kovových? A Complete Guide to Kovových Materials

Introduction to Kovových Materials

Kovových materials are making waves in various industries, and for good reason. But what exactly is kovových? This term encapsulates a range of materials that possess unique properties, making them indispensable across multiple applications. From construction to manufacturing, the versatility of kovových is truly remarkable.

Imagine building a structure that can withstand extreme conditions or creating components that offer both strength and lightweight benefits. Kovových materials make these possibilities a reality. As we delve deeper into this captivating subject, you’ll discover the diverse types of kovových, their numerous advantages, and how they fit seamlessly into modern design and engineering practices. Whether you’re an industry professional or just curious about innovative materials, understanding kovových will open your eyes to new opportunities. Let’s explore!

Types of Kovových Materials

Kovových materials come in a variety of forms, each with its unique properties and applications. One common type is ferrous metals, which primarily contain iron. These are known for their strength and durability, making them ideal for construction and heavy-duty machinery.

Then there are non-ferrous metals like aluminum and copper. These materials resist corrosion and have excellent conductivity, perfect for electrical applications. Another category includes alloys, which combine two or more elements to enhance specific characteristics. Stainless steel is a popular alloy that offers both aesthetic appeal and outstanding resistance to rust.

Advanced composites blend metallic components with other materials to create lightweight yet strong solutions. Each type serves distinct purposes across various industries, showcasing the versatility of kovových elements in modern manufacturing processes.

Benefits and Uses of Kovových Materials

Kovových materials offer a range of benefits that make them highly sought after in various applications. One of the primary advantages is their exceptional strength-to-weight ratio. This property allows for lightweight constructions without compromising durability. Additionally, kovových materials exhibit excellent corrosion resistance. This makes them ideal for use in environments where exposure to moisture and chemicals is common.

The versatility of these materials extends to numerous industries. From aerospace components to automotive parts, their applications are diverse and impactful.

Moreover, kovových materials can be easily molded into complex shapes. This adaptability enables innovative designs that enhance functionality while maintaining aesthetic appeal.

Their thermal conductivity further adds to their appeal in electronic devices and heat exchangers, ensuring efficient performance across different sectors. The combination of these features opens up endless possibilities for engineers and designers alike.

Common Industries That Use Kovových Materials

Kovových materials have become integral across various industries due to their unique properties. The automotive sector, for instance, relies heavily on these materials for manufacturing parts that require durability and lightweight characteristics. The aerospace industry also benefits significantly from kovových usage. Components made from these materials help in reducing overall weight while maintaining strength and integrity during flight.

Construction is another area where kovových shines. From structural beams to roofing elements, the resilience of these materials is crucial for building safety and longevity. In electronics, kovových serves as an essential component in circuit boards and connectors. Their conductivity makes them ideal for efficient energy transfer. The medical field employs kovových for surgical instruments and implants, where precision and reliability are paramount. Each application showcases the versatility of Kovových materials across diverse sectors.

How to Choose the Right Kovových Material for Your Project

Choosing the right kovových material for your project can feel overwhelming. Start by assessing the specific requirements and goals of your project. Consider factors like strength, weight, and durability. Next, think about environmental conditions. Will the material be exposed to moisture or extreme temperatures? This can influence your choice significantly.

It’s also essential to evaluate cost-effectiveness. Some kovových materials may offer superior qualities but come at a higher price point. Be sure to balance performance with budget constraints. Don’t forget about manufacturability as well. Certain materials might require specialized tools or processes that could complicate production timelines.

Consult industry experts or resources if you’re uncertain. Their insights can guide you toward making an informed decision tailored to your unique needs and specifications.

Challenges and Limitations of Using Kovových Materials

Kovových materials, while highly versatile, come with their own set of challenges. One notable limitation is the cost. High-quality kovových options can be expensive to source and process. Another challenge lies in durability. Certain types may not withstand extreme temperatures or harsh environments as well as anticipated. This can lead to premature wear and tear.

Additionally, welding and fabrication processes for kovových materials often require specialized skills. Not all workers are trained adequately, which can impact project timelines. There’s also the issue of corrosion resistance. Some kovových materials may need protective coatings to prevent degradation over time, adding another layer of complexity to maintenance. Compatibility with other materials might pose a problem during assembly. Ensuring that different components work together seamlessly requires careful planning and consideration from designers and engineers alike.

Sustainability and Environmental Impact of Kovových Materials

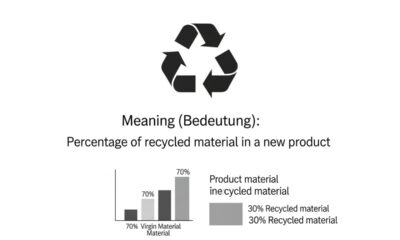

Kovových materials are making strides in sustainability. Their production often requires less energy compared to traditional materials. This means a lower carbon footprint, which is crucial for our planet. Recycling plays a significant role in their environmental impact. Many kovových products can be repurposed at the end of their life cycle. This reduces waste and conserves valuable resources.

Moreover, these materials frequently contain recycled content right from the start. Using pre-existing metals minimizes the need for new raw material extraction, preserving natural habitats. Some manufacturers prioritize eco-friendly practices throughout their supply chain. From sourcing to processing, they implement methods that lessen environmental harm.

As industries become more conscious of sustainability, demand for kovových materials continues to grow. They align well with green initiatives while maintaining performance standards essential for various applications.

Future Developments in the Use of Kovových Materials

The future of kovových materials is promising, driven by advancements in technology and increasing demand across various sectors. Researchers are exploring innovative alloys that enhance strength while reducing weight. These developments could revolutionize industries such as automotive and aerospace.

Smart materials integrated with sensors are also on the horizon. Imagine kovových components that can monitor stress levels or temperature changes in real-time, improving safety and performance. Moreover, 3D printing technologies are set to transform how we produce kovových items. This method allows for more complex designs with minimal waste, leading to greater efficiency.

Sustainability will play a crucial role too. The focus will shift towards recyclable and eco-friendly kovových solutions that meet both functional needs and environmental responsibilities. As these trends evolve, the applications for kovových materials will continue to expand significantly across multiple fields.

Conclusion: The Versatility and

Versatility and adaptability define kovových materials in an ever-evolving landscape. Their unique properties make them suitable for a wide range of applications, from construction to aerospace. As industries continue to innovate, the demand for these materials is likely to grow.

With advancements in technology, new types of kovových materials are entering the market. This growth opens up exciting possibilities for engineers and designers looking to enhance their projects. The benefits they offer can lead to increased efficiency and reduced costs.

The challenge lies in selecting the right material for specific needs while considering sustainability factors. It’s crucial not only to focus on performance but also on environmental impact as we move toward more eco-friendly solutions.

Kovových materials stand at the forefront of modern manufacturing and design. Their ability to meet high standards makes them invaluable across various sectors, ensuring that they will remain integral components of future innovations.

Blog

WIAA Arrowhead High School Waiver Lawsuit: What It Means for Student Athletes, Schools, and the Future of Eligibility Rules

High school sports are often seen as a rite of passage — Friday night lights, packed gyms, community pride, and young athletes chasing big dreams. But sometimes, the rules behind those moments become the real headline. The wiaa arrowhead high school waiver lawsuit has done exactly that, pulling a local eligibility dispute into a broader legal and policy conversation about fairness, governance, and the balance between institutional authority and individual opportunity.

For startup founders, entrepreneurs, and tech professionals who follow how systems evolve under pressure, this case offers something deeper than sports drama. It’s a live example of how legacy organizations adapt — or struggle to adapt — when confronted with legal scrutiny and public accountability.

Let’s unpack what happened, why it matters, and what lessons it holds beyond the playing field.

Understanding the WIAA and Its Authority

At the center of the dispute is the Wisconsin Interscholastic Athletic Association, better known as the WIAA. The WIAA governs high school athletics across Wisconsin, setting eligibility standards, transfer rules, and compliance frameworks for member schools.

Like many state athletic associations, the WIAA operates as a private, nonprofit organization. Yet its decisions deeply impact public school students. That hybrid role — private governance with public consequence — often creates legal gray areas.

Eligibility rules typically cover:

- Student transfers between schools

- Residency requirements

- Academic standing

- Athletic participation history

When students transfer schools, especially if they are athletes, associations like the WIAA may require them to sit out a season unless a waiver is granted. These waivers are designed to prevent recruitment abuses and maintain competitive balance.

But when a waiver is denied, the consequences can be immediate and personal — particularly for students hoping to secure scholarships or maintain athletic development.

The Role of Arrowhead High School

The case specifically involves Arrowhead High School, a prominent public high school in Hartland, Wisconsin, known for strong athletic programs.

Arrowhead has historically been competitive in multiple sports, making eligibility decisions especially sensitive. When a transfer student sought a waiver to compete and that waiver was denied, the dispute escalated beyond administrative review.

That denial triggered the legal conflict now widely referred to as the wiaa arrowhead high school waiver lawsuit.

What Sparked the WIAA Arrowhead High School Waiver Lawsuit?

While specific details of any legal case depend on filings and judicial interpretation, waiver lawsuits typically revolve around one core issue: whether the governing body applied its rules fairly and lawfully.

In this instance, the dispute reportedly centered on whether the WIAA:

- Applied eligibility rules consistently

- Provided due process in reviewing the waiver

- Acted within its legal authority

- Violated constitutional protections such as equal protection or due process

When a student’s athletic eligibility is denied, families sometimes argue that the decision unfairly limits educational opportunity. Athletic participation is not merely extracurricular for many students — it can be a pathway to scholarships, visibility, and personal advancement.

The lawsuit effectively asked whether a private athletic association’s rules could override an individual student’s claim to fair treatment.

Legal Framework: Where Sports Meet Constitutional Law

To understand why the wiaa arrowhead high school waiver lawsuit matters, it helps to zoom out.

Courts often wrestle with one central question: Is the WIAA a private actor or a state actor?

If it is considered purely private, courts tend to defer to its internal rules. But if its actions are seen as intertwined with public schools — and therefore government authority — constitutional protections may apply.

This distinction determines whether claims like:

- Violation of due process

- Equal protection concerns

- Arbitrary or capricious decision-making

can move forward.

For business leaders, this is reminiscent of platform governance disputes. When does a private organization that controls public access become subject to broader accountability standards?

The parallels are striking.

Why Waiver Systems Exist in the First Place

Transfer rules were originally created to prevent athletic recruiting at the high school level. Without them, schools with strong sports reputations could attract talent in ways that undermine competitive fairness.

Waivers are intended to serve as safety valves. They allow flexibility when:

- A family relocates for legitimate reasons

- Academic programs require transfer

- Hardship situations occur

- There was no athletic motivation behind the move

But waiver systems rely heavily on discretion. And discretion, when exercised inconsistently, invites scrutiny.

In the wiaa arrowhead high school waiver lawsuit, the central tension lies in whether that discretion was used appropriately.

Governance Tension: Control vs. Opportunity

This case highlights a broader philosophical debate.

Athletic associations argue that strict enforcement protects competitive integrity. Families argue that rigid enforcement can unfairly penalize students.

Here’s a simplified comparison:

| Stakeholder | Primary Concern | Risk if Overcorrected |

| WIAA | Prevent recruitment abuse | Appears inflexible or arbitrary |

| Schools | Maintain competitive fairness | Reputational damage |

| Students/Families | Fair opportunity to compete | Loss of scholarships or exposure |

| Courts | Legal compliance | Overreach into private governance |

The lawsuit sits precisely at this intersection.

The Ripple Effect on Student Athletes

For student athletes, eligibility isn’t theoretical.

A denied waiver can mean:

- Missing an entire season

- Losing recruitment visibility

- Emotional distress

- Interrupted athletic development

In competitive sports environments, timing matters. A junior year season, for example, can be critical for college scouts.

This is why disputes escalate quickly. What may appear to administrators as rule enforcement can feel to families like a life-altering setback.

Institutional Risk and Reputation

From a governance perspective, lawsuits like the wiaa arrowhead high school waiver lawsuit expose organizations to several risks:

- Legal costs

- Public criticism

- Precedent-setting rulings

- Policy revisions

For Arrowhead High School, the case also carries reputational implications. High-profile eligibility disputes can attract media coverage and public debate, especially in sports-driven communities.

In today’s digital landscape, these issues spread quickly through social platforms, reshaping narratives before legal outcomes are finalized.

The Broader Trend: Increased Legal Challenges to Athletic Associations

This case is not isolated. Across the United States, state athletic associations have faced growing legal scrutiny.

Factors contributing to this trend include:

- Greater awareness of student rights

- Increased competition for college scholarships

- Heightened parental advocacy

- Social media amplification

Athletics are no longer insulated from legal oversight. Just as startups face regulatory pressure when they scale, governing bodies face scrutiny when their authority affects individual opportunity.

Policy Implications Moving Forward

Whether the lawsuit results in a court ruling, settlement, or policy change, it could influence how waiver systems are structured in the future.

Possible outcomes might include:

- More transparent waiver criteria

- Clearer appeal processes

- Defined timelines for decisions

- Standardized documentation requirements

Greater transparency tends to reduce litigation risk. When decision-making frameworks are clear and consistently applied, disputes are less likely to escalate.

For founders and executives, this reinforces a familiar lesson: ambiguity invites challenge.

Lessons for Organizational Leaders

Though rooted in high school sports, the wiaa arrowhead high school waiver lawsuit offers insights relevant to any organization that governs participation.

First, discretionary authority must be paired with documented standards. Second, communication matters as much as policy. Third, reputational exposure grows when decisions impact individual opportunity.

In governance, fairness is not just about internal confidence — it’s about external perception.

Organizations that fail to align those two dimensions often find themselves defending decisions in court rather than refining them internally.

The Human Dimension

Behind every lawsuit is a student.

Eligibility disputes can quickly become deeply personal. Families invest time, money, and emotion into athletic development. When a rule blocks participation, it can feel like the system is indifferent to individual circumstances.

Balancing compassion with compliance is one of the hardest challenges for regulatory bodies.

The WIAA, like similar associations nationwide, operates within that tension daily.

What Happens Next?

Legal proceedings often unfold slowly. Courts may dismiss claims, narrow issues, or require additional evidence. Sometimes cases settle quietly. Other times, they produce rulings that reshape policy statewide.

Regardless of the outcome, the conversation sparked by the wiaa arrowhead high school waiver lawsuit will likely influence how schools and associations think about eligibility governance moving forward.

The most probable long-term shift is not elimination of waiver rules — but refinement.

Conclusion: A Case That Extends Beyond the Field

At first glance, the wiaa arrowhead high school waiver lawsuit appears to be a localized eligibility dispute. In reality, it represents something broader: the ongoing negotiation between institutional authority and individual opportunity.

For student athletes, the stakes are immediate and personal. For schools and governing bodies, the stakes are structural and reputational. For legal observers and business leaders, the case serves as a reminder that systems built decades ago must continually evolve to meet modern expectations of transparency and fairness.

In every regulated environment — whether athletics, technology, or finance — governance frameworks are strongest when they are clear, consistent, and adaptable.

High school sports may feel far removed from startup ecosystems, but the underlying lesson is universal: rules matter, but how they are applied matters even more.

Blog

Matarecycler: Turning Waste into Opportunity in the Circular Economy

In a world where landfills are growing faster than cities and raw materials are becoming increasingly expensive, the question is no longer whether we need better recycling systems — it is how quickly we can build them. This is where matarecycler enters the conversation. More than just a recycling initiative, matarecycler represents a shift in thinking: waste is not an endpoint, but a starting point. For startup founders, entrepreneurs, and technology leaders, this shift signals both responsibility and opportunity.

The global economy is undergoing a structural transformation. Supply chains are fragile. Climate regulations are tightening. Consumers are demanding accountability. Businesses that once viewed recycling as a compliance checkbox now see it as a competitive advantage. Matarecycler sits at the intersection of sustainability, innovation, and digital infrastructure — three pillars shaping the next decade of growth.

The Business Case Behind Matarecycler

Recycling is no longer purely environmental; it is financial. Companies are under pressure to reduce operational costs while maintaining brand integrity. Raw material volatility has pushed manufacturers to explore alternative sourcing strategies. Recycled materials often cost less, reduce carbon emissions, and provide insulation against supply disruptions.

Matarecycler operates within this strategic context. By optimizing material recovery and integrating technology into waste processing workflows, it demonstrates how recycling can become a profit center rather than a cost burden. For founders building sustainable startups, the lesson is clear: circular models are not just ethical — they are scalable.

The rise of the circular economy underscores this shift. Instead of a linear “take, make, dispose” approach, businesses are designing systems where materials continuously flow through cycles of reuse and regeneration. Matarecycler aligns with this framework by creating structured pathways for waste transformation.

Matarecycler and the Circular Economy Revolution

The circular economy is often discussed in theory, but its implementation requires infrastructure, logistics, and technological coordination. Matarecycler addresses these practical realities. It focuses on recovering usable materials from discarded products and reintegrating them into production streams.

This approach reduces landfill dependency and lowers carbon footprints, but it also creates measurable economic value. Consider the following simplified comparison:

| Factor | Traditional Linear Model | Circular Model with Matarecycler |

| Raw Material Cost | High and volatile | Lower through recycled inputs |

| Waste Management Cost | Ongoing disposal expense | Offset by material recovery value |

| Carbon Emissions | Higher | Significantly reduced |

| Brand Perception | Neutral or negative | Sustainability-driven trust |

For tech professionals analyzing sustainability metrics, the difference is not marginal — it is structural. The circular approach fundamentally changes cost curves and environmental impact.

Technology as the Engine of Matarecycler

At its core, matarecycler is powered by technology. Digital tracking systems, AI-assisted material sorting, and data-driven logistics optimization transform traditional recycling operations into intelligent ecosystems.

Artificial intelligence enhances sorting accuracy, reducing contamination rates in recyclable streams. IoT sensors monitor collection routes and bin capacity, ensuring efficient pickups. Data analytics forecast material flows, helping operators plan processing capacity. When these elements are integrated, waste management becomes a predictive, scalable system rather than a reactive one.

For startup founders, this signals a broader opportunity. Sustainability technology — often referred to as “climate tech” — is attracting unprecedented investment. Venture capital is flowing into businesses that combine environmental impact with scalable digital platforms. Matarecycler represents a model where sustainability and innovation converge.

Real-World Relevance for Entrepreneurs

Entrepreneurs often ask: how does recycling innovation affect my business model? The answer depends on your industry, but the implications are widespread.

E-commerce companies face packaging waste challenges. Hardware startups must address electronic waste. Manufacturing firms must manage scrap and excess materials. In each case, partnering with or learning from matarecycler-style systems can unlock operational efficiencies.

There is also a branding dimension. Consumers increasingly evaluate companies based on sustainability credentials. Transparent waste recovery practices build trust. Investors, especially ESG-focused funds, examine lifecycle impact metrics before allocating capital. Matarecycler’s structured approach to material recovery aligns with these investor expectations.

Startups that embed circular principles early avoid costly retrofits later. Instead of redesigning supply chains under regulatory pressure, they build resilience from the outset.

Environmental Impact with Measurable Outcomes

It is easy to speak about sustainability in abstract terms. The real question is measurement. Matarecycler contributes to environmental goals by reducing landfill volume, lowering greenhouse gas emissions, and minimizing resource extraction.

Material recovery decreases the need for virgin resource mining. This reduces deforestation, water contamination, and energy-intensive extraction processes. Recycled aluminum, for example, requires significantly less energy than producing new aluminum from ore. The same principle applies across multiple material categories.

By tracking recovery rates and emission reductions, matarecycler enables transparent reporting. For publicly traded companies, such reporting supports sustainability disclosures. For startups, it strengthens pitches to impact-driven investors.

Regulatory Landscape and Strategic Advantage

Governments worldwide are tightening environmental regulations. Extended Producer Responsibility (EPR) laws require manufacturers to take responsibility for product lifecycle impacts. Carbon pricing mechanisms increase the cost of waste-intensive operations.

Businesses that integrate systems like matarecycler gain a proactive advantage. Instead of reacting to compliance mandates, they shape their operations around sustainability from the beginning.

Regions across Europe and Asia are already enforcing stricter waste diversion targets. North American markets are rapidly following suit. Companies ignoring these signals risk higher compliance costs and reputational damage.

Forward-thinking entrepreneurs recognize that regulation often accelerates innovation. By adopting recycling-focused models early, they position themselves ahead of competitors who wait until mandates become unavoidable.

Digital Transparency and Consumer Trust

One of the most powerful aspects of matarecycler is transparency. Modern consumers expect visibility into supply chains. Blockchain-based tracking, digital material passports, and traceable recovery documentation are becoming industry norms.

When customers can verify that a product incorporates recycled inputs, trust increases. This is particularly important in sectors like electronics, fashion, and consumer goods, where environmental scrutiny is high.

Digital verification systems not only enhance brand credibility but also protect against greenwashing accusations. In an era where misleading sustainability claims can trigger legal action, authentic data-backed reporting is essential.

Matarecycler-style platforms provide the infrastructure necessary to validate environmental impact claims with credible metrics.

Economic Resilience Through Resource Independence

Global disruptions have exposed the vulnerability of resource-dependent supply chains. Geopolitical tensions, shipping bottlenecks, and commodity price spikes highlight the importance of local material recovery systems.

By recycling materials domestically, businesses reduce dependence on international raw material markets. Matarecycler contributes to localized circular ecosystems, where materials circulate within regional economies.

This model enhances resilience. It stabilizes input costs and shortens supply chains. For startups scaling operations, predictable material access can determine profitability.

The strategic advantage lies not only in sustainability but also in risk mitigation.

Innovation Opportunities Inspired by Matarecycler

The concept of matarecycler opens broader innovation pathways. Entrepreneurs can explore adjacent solutions such as waste analytics platforms, smart collection infrastructure, or biodegradable material design.

Investors increasingly seek ventures that combine measurable impact with scalable technology. Climate-oriented accelerators and sustainability funds are expanding rapidly. Founders who align with circular principles position themselves within this high-growth investment ecosystem.

Moreover, collaboration between technology developers and recycling operators fosters cross-industry innovation. Data platforms can integrate with processing facilities. Hardware startups can design products optimized for disassembly and material recovery.

The future of waste management is collaborative, digital, and intelligent.

Overcoming Implementation Challenges

No transformation is without obstacles. Recycling systems face contamination issues, infrastructure gaps, and inconsistent consumer participation. Scaling matarecycler-style operations requires education, technology integration, and stakeholder coordination.

However, these challenges also create opportunities for creative problem-solving. Gamified recycling apps can incentivize participation. AI models can improve sorting precision. Partnerships between municipalities and private enterprises can strengthen collection networks.

The key insight for founders is this: complexity does not signal impossibility. It signals room for innovation.

Matarecycler as a Blueprint for the Future

The shift toward sustainability is not temporary. It is structural. Climate risks, regulatory pressures, and investor expectations are converging. Businesses that adapt will thrive. Those that resist will struggle.

Matarecycler represents more than a recycling process — it is a blueprint for circular value creation. It demonstrates how waste streams can become revenue streams, how environmental responsibility can align with profitability, and how digital systems can transform traditional industries.

For entrepreneurs, the message is clear: sustainability is not a side project. It is a core business strategy. Embedding circular principles into product design, supply chain management, and customer engagement builds long-term resilience.

For tech professionals, the opportunity lies in building the infrastructure that powers this transformation — from AI sorting systems to blockchain traceability platforms.

For investors, the growth potential is undeniable. As global economies transition toward low-carbon models, circular solutions will command increasing capital attention.

Conclusion: Waste as the Next Frontier of Innovation

The world is redefining value. Materials once discarded are now assets. Processes once overlooked are now strategic priorities. In this evolving landscape, matarecycler stands as a symbol of what modern business can achieve when sustainability and technology converge.

Startup founders, entrepreneurs, and digital leaders should not view recycling as peripheral. It is central to operational efficiency, brand credibility, and long-term competitiveness. By adopting circular strategies inspired by matarecycler, businesses transform environmental responsibility into measurable growth.

The next wave of innovation will not come solely from new products, but from smarter systems. And in that future, waste will no longer represent loss — it will represent opportunity.

Blog

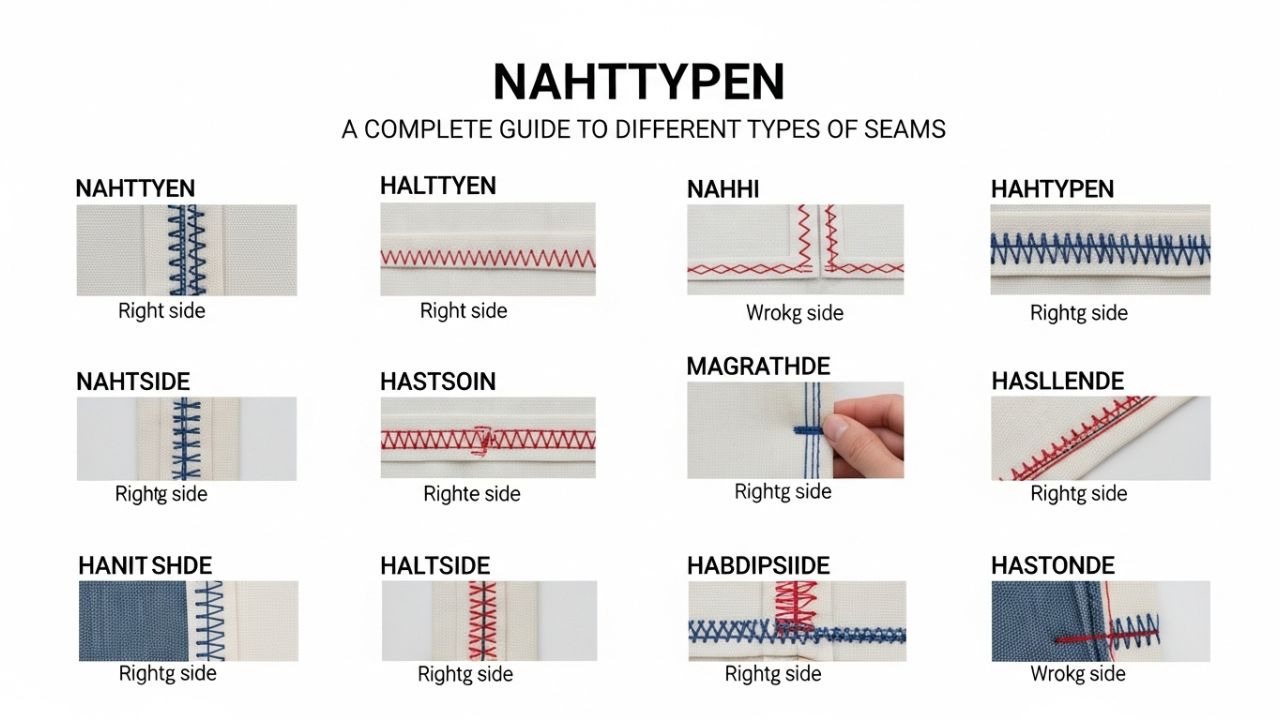

Nahttypen: The Hidden Engineering Language Behind Stronger Products and Smarter Manufacturing

In the world of product design and manufacturing, most people talk about innovation in terms of software, AI, or automation. But beneath every groundbreaking machine, electric vehicle frame, architectural structure, or industrial tool lies something far more fundamental: how materials are joined together. This is where nahttypen—the different types of weld seams—quietly determine whether a product lasts decades or fails under pressure.

For startup founders building hardware, engineers scaling prototypes into mass production, or tech professionals optimizing manufacturing workflows, understanding nahttypen is not just technical trivia. It is a strategic advantage. The right seam design influences cost, durability, safety, aesthetics, and even regulatory approval. And in competitive markets, those margins matter.

Let’s unpack what nahttypen really mean, why they matter far beyond the welding floor, and how modern businesses can use this knowledge to build better products and smarter operations.

What Are Nahttypen and Why Should Tech Leaders Care?

The term nahttypen comes from German engineering terminology and translates directly to “types of seams” or “types of weld joints.” In manufacturing, it refers to the structural forms used to join two or more components permanently, typically through welding processes.

While welders focus on execution, founders and product designers should focus on implications. Each nahttypen affects:

- Structural integrity

- Load distribution

- Fatigue resistance

- Production time

- Material consumption

- Visual finish

If you’re developing a robotics platform, constructing modular data center racks, or building IoT-enabled industrial devices, the seam type can change everything from production scalability to warranty claims.

In short, nahttypen are engineering decisions with business consequences.

The Core Nahttypen Used in Modern Manufacturing

To understand the strategic impact, we first need to explore the most common nahttypen used in industry today.

Butt Weld (Stumpfnaht)

The butt weld joins two components aligned in the same plane. It is one of the most efficient and structurally clean seam types when executed correctly.

In high-precision manufacturing—such as automotive chassis or pressure vessels—butt welds allow for smooth load transfer across materials. They minimize stress concentrations and often require less finishing work when properly aligned.

For startups producing lightweight structures, butt welds can reduce excess material overlap, keeping designs lean and cost-effective.

Fillet Weld (Kehlnaht)

The fillet weld connects two surfaces at roughly a right angle. It is one of the most common nahttypen in steel structures and mechanical assemblies.

You’ll see fillet welds in:

- Frame constructions

- Support brackets

- Machinery housings

- Structural reinforcements

From a business perspective, fillet welds are popular because they are relatively easy to execute and adaptable to automated welding systems. However, improper sizing can create weak points or unnecessary material costs.

Lap Joint (Überlappnaht)

Lap joints involve overlapping two materials and welding along the edge. This nahttypen approach is often used when materials differ in thickness or when surface area needs reinforcement.

While lap joints can increase strength, they also add weight and material usage. For industries prioritizing lightweight engineering—like aerospace or electric mobility—designers must balance strength with efficiency.

Corner and Edge Welds

Corner welds are common in box-like structures, while edge welds join parallel edges. These nahttypen are frequently used in enclosures, cabinets, and sheet metal fabrication.

In hardware startups producing IoT devices or industrial enclosures, choosing the correct seam affects not only durability but also visual branding. Clean, minimal weld seams communicate quality.

Comparing Nahttypen: A Strategic Overview

Below is a simplified comparison to highlight how different seam types impact production and performance.

| Nahttypen (Weld Type) | Structural Strength | Material Efficiency | Production Complexity | Typical Use Case |

| Butt Weld | Very High | High | Moderate | Pressure vessels, frames |

| Fillet Weld | High | Moderate | Low to Moderate | Structural supports |

| Lap Joint | High | Lower | Low | Reinforced assemblies |

| Corner Weld | Moderate to High | Moderate | Moderate | Boxes, enclosures |

| Edge Weld | Moderate | High | Low | Sheet metal parts |

For founders evaluating manufacturing partners, this table becomes a lens for cost estimation, automation feasibility, and long-term reliability.

Nahttypen and Automation: The Industry 4.0 Connection

We cannot talk about modern nahttypen without addressing automation. As smart factories expand and robotics become mainstream, seam selection directly influences how easily welding can be automated.

Robotic welding systems thrive on repeatable geometries. Butt and fillet welds are often easier to standardize in high-volume production lines. More complex seam types may require advanced sensor systems or adaptive programming.

Companies like KUKA and ABB have transformed industrial welding by integrating AI-driven robotics capable of handling diverse nahttypen with precision.

For tech startups, this means seam design should align with future scalability. A prototype built with manual welding might not translate efficiently into robotic mass production. Early engineering decisions matter.

Material Science and Nahttypen: The Hidden Risk Factor

Different materials behave differently under heat and stress. Stainless steel, aluminum, carbon steel, and titanium each respond uniquely during welding.

Poor selection of nahttypen can result in:

- Heat distortion

- Micro-cracking

- Corrosion vulnerability

- Fatigue failure

For example, aluminum structures—common in electric vehicles and drones—require careful seam design to avoid weakening the heat-affected zone.

Companies like Tesla invest heavily in welding innovation because seam integrity directly affects vehicle safety and longevity.

For entrepreneurs building physical products, overlooking material behavior in seam selection can result in recalls, liability exposure, and brand damage.

Cost Implications of Choosing the Wrong Nahttypen

From a financial perspective, seam types influence:

- Labor time

- Welding consumables

- Inspection requirements

- Rework rates

- Warranty claims

A fillet weld might seem cheaper initially but may require larger material sections for equivalent strength compared to a well-designed butt weld. Conversely, overengineering seams increases weight and material cost unnecessarily.

Manufacturing leaders treat nahttypen decisions as ROI calculations, not just technical choices.

Aesthetic and Brand Considerations

In high-end consumer hardware or architectural applications, weld seams are visible. Poor seam selection or execution can compromise brand perception.

Think about industrial design firms producing premium metal furniture or smart home hardware. Clean, seamless joints communicate precision and trust.

Even technology giants like Apple obsess over invisible joints and flawless finishes. While they may use advanced bonding techniques rather than traditional welding, the underlying principle remains: the seam tells a story about quality.

For founders building hardware brands, nahttypen choices affect not just engineering but storytelling.

Regulatory and Safety Standards

Certain industries—oil and gas, aerospace, medical devices—are governed by strict welding codes. Seam types must comply with standards that dictate joint preparation, inspection protocols, and load-bearing capacity.

International frameworks such as those developed by International Organization for Standardization shape how nahttypen are documented and validated.

Failure to align seam design with regulatory requirements can delay product launches and increase certification costs.

For startups aiming at regulated markets, understanding seam classification early reduces risk.

Nahttypen in Sustainable Manufacturing

Sustainability is no longer optional. Seam types impact:

- Energy usage during welding

- Material waste

- Product lifespan

- Recyclability

A well-optimized seam reduces filler material consumption and minimizes rework. Longer-lasting products also reduce environmental impact over time.

Forward-thinking manufacturers are redesigning seam strategies to improve lifecycle efficiency. In green construction and renewable energy systems, smarter seam selection supports sustainability goals.

Practical Advice for Founders and Product Teams

If you’re building hardware or managing a technical manufacturing operation, here’s a strategic approach to nahttypen:

First, involve welding engineers early in the design phase. Seam type should never be an afterthought.

Second, evaluate how the seam will scale. What works in a low-volume prototype may fail in automated production.

Third, consider lifecycle costs rather than upfront expenses alone.

Fourth, align seam selection with brand identity if aesthetics matter.

Finally, document seam rationale thoroughly. Investors and regulators appreciate disciplined engineering processes.

The Future of Nahttypen: Smart Monitoring and AI

Emerging technologies are making seam integrity measurable in real time. AI-driven inspection systems now monitor weld penetration, temperature, and micro-defects during production.

Smart factories increasingly integrate seam data into predictive maintenance platforms. Instead of discovering failure after deployment, manufacturers can identify risk patterns early.

As digital twins become mainstream, nahttypen decisions will be simulated before physical production even begins. That means founders who understand seam strategy today will move faster tomorrow.

Conclusion: Why Nahttypen Are a Strategic Advantage

At first glance, nahttypen may seem like a narrow engineering topic. But in reality, seam selection sits at the intersection of design, cost, automation, safety, and brand perception.

For startup founders and tech professionals entering hardware or industrial markets, understanding nahttypen transforms manufacturing from a black box into a strategic tool.

The companies that win are not just those with the best software or the boldest vision. They are the ones that build products strong enough to survive real-world stress—physically and competitively.

In manufacturing, the seam is never just a seam. It is a commitment to strength, precision, and long-term thinking.

-

Travel2 months ago

Travel2 months agoEnntal: Scenic Beauty, History, and Outdoor Adventures

-

Blog2 months ago

Blog2 months agoShani Levni Explained: Name Origin, Symbolism, and Usage

-

Fashion2 months ago

Fashion2 months agoFashion’s Never Finished GIF Social Experiment: Meaning, Message, and Impact

-

Law2 months ago

Law2 months agoStacey Huels Lawsuit: Key Allegations, Timeline, and Updates

-

Blog2 months ago

Blog2 months agoNovaPG Meaning: What It Is, How It Works, and Why It Matters

-

Blog2 months ago

Blog2 months agoWhy Portar Leisa Is Gaining Attention in 2026 – Complete Guide

-

Blog1 month ago

Blog1 month agoRecyclatanteil Explained: Meaning, Importance, and Real-World Examples

-

Blog1 month ago

Blog1 month agoJack Şoparov Explained: Meaning, Background, and Why It’s Trending